Dendritics D500 Weighing Pan - Evaluations #1 |

|

|

![]()

|

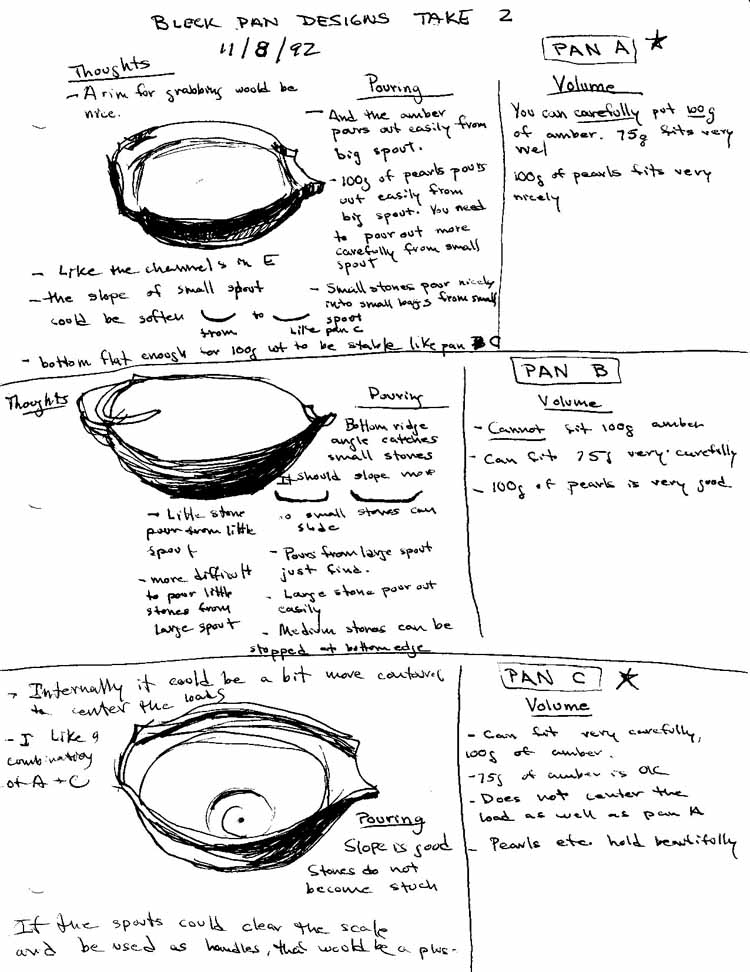

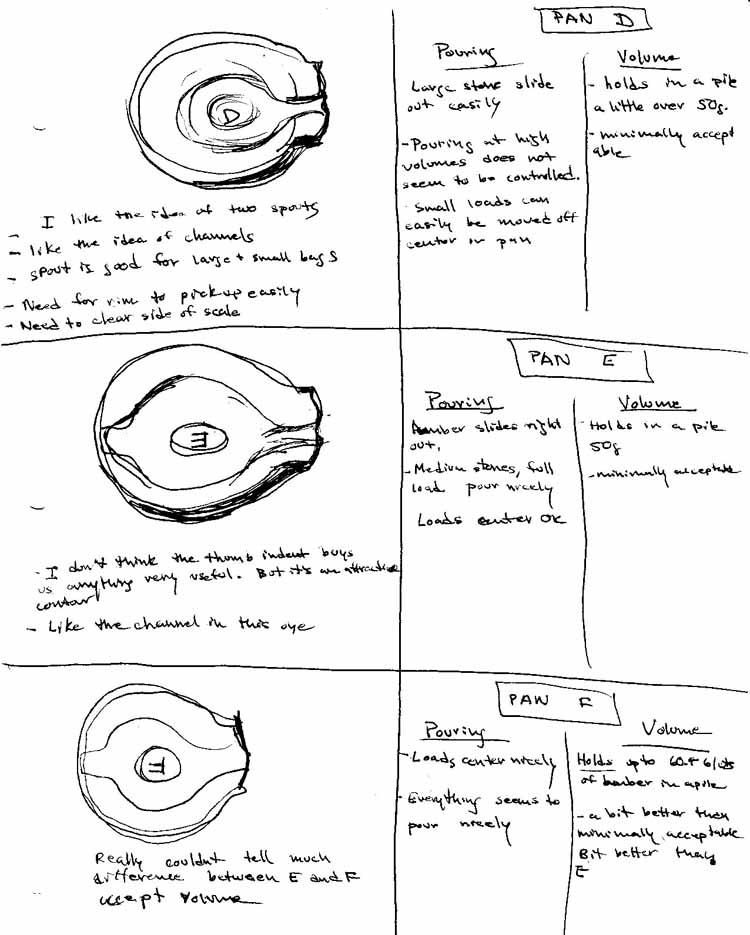

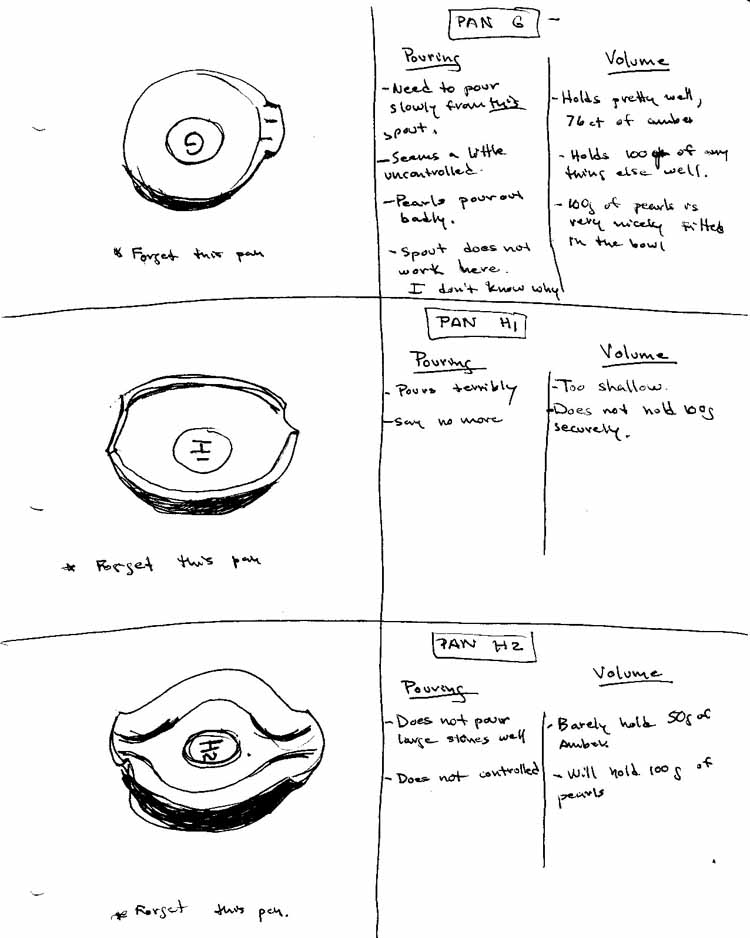

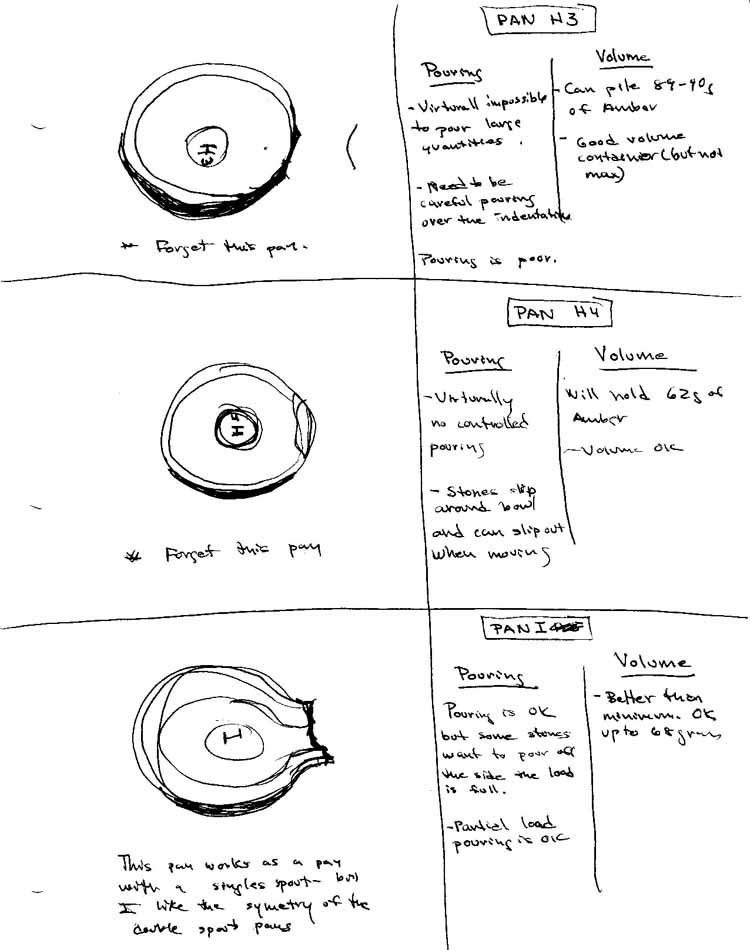

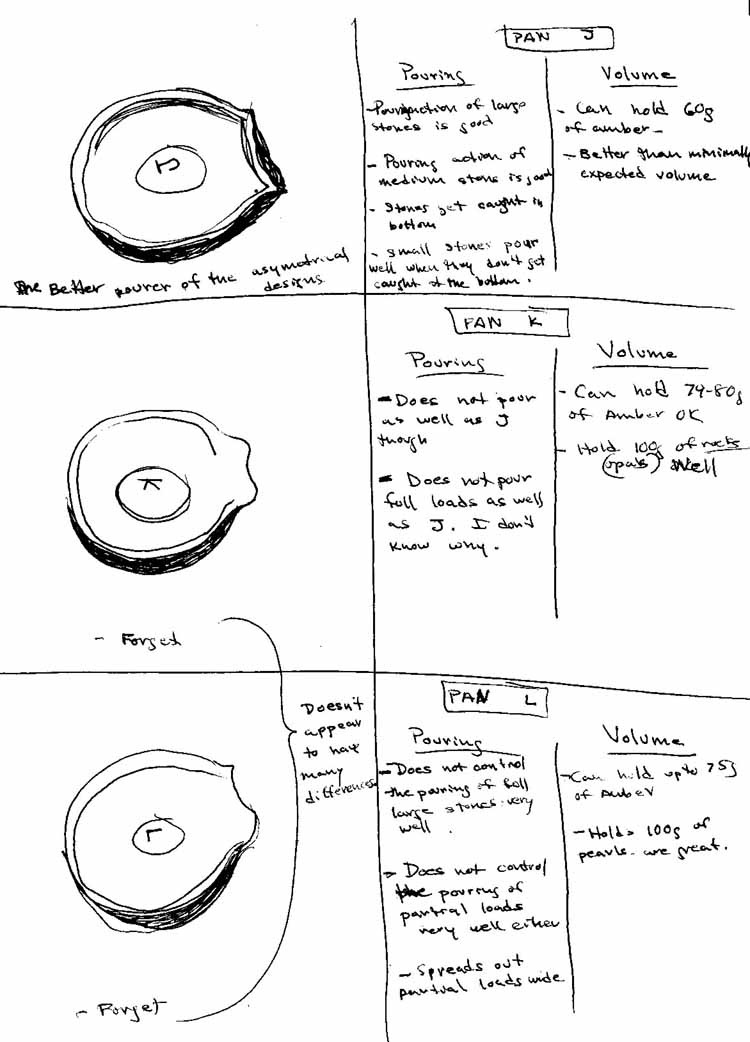

(November 1995) In the development process for the D500 weighing pan many many designs were considered and discarded. This gives a feeling for that process. In general none of the pans interact well with the cover. There is a need for a higher pan lip or thumb recesses in cover to allow a fully loaded pan to be picked up easily. The symmetrical, double spouted, pans work very nicely and are preferred by JB and I as a better idea. Itís a nice innovation to control pouring of large stones as well as small stones. And a modified internal contour is preferable when it helps center the load (as in pan E ) but allows stones to flow out smoothly (as in PAN F).

Some pans are higher than other pans. Should we not be dealing with a uniformed height of pan which is defined by the closed draftshield? The height of the pan does effect how the pan holds and pours a full or heavy load.

The weight locating area at the bottom of the pan need not be defined by a full unbroken circle. The weight locating area should be determined be the diameter of the bottom of the weight. This will effect pouring and it would be helpful to evaluate if the pans were more uniform in this way. The weight location area can be contoured for pouring as long as it is flat, centers the weight and the location area matches the bottom diameter of the weight . The weight location area in Pan B and Pan C has been modified by JB to facilitate pouring. |

PAN A/ is a promising pan. It holds 100g of amber piled up carefully. It will hold every other material nicely and easily. It needs a weight locating area. The angle of the slope of the bowl is a bit steep as an excessive angle is required to get the last stones out at the end of a pour. Internal contouring as done in pan E and Pan F would help. Also I would like to see the slope of the smaller spout eased from this to something like this. An edge around the rim would make it much easier to pick up from the scale.

PAN B/ JB likes the "little finger lip". But we found that it did not behave as well as PAN A or PAN C.

PAN C/ This pan too will hold 100g of amber piled up. The very gentle angle makes for very controlled pouring however it does not center partial loads as well as Pan A. The slope on the small spout works better than spout size of PAN A. But JB feels the size of the spout is a bit too big for the small baggies.

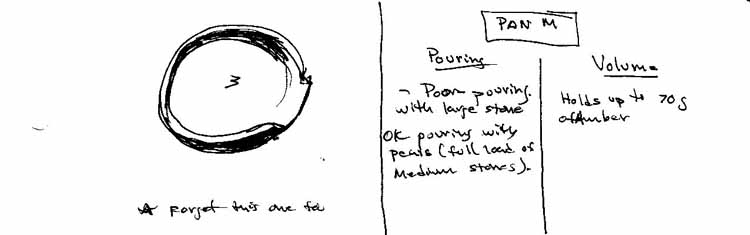

PANS D, G, H1, H2, H3,H4,K,L,M / are all pans that failed in some way. They can all be eliminated.

![]()

Images and webpage designs © 2001-2026 your webmaster, jb and Dendritics Inc. [-]